Defence Exports Touch Rs 8,000 Crore In H1 As Sector Gains From Make In India

by Ranjit Bhushan

Rohit Bedi, co-founder of AROO, India’s first defence start-up that produces specialised defence clothing, swears by the government’s Make-in-India program.

“Our vision began with the Indian government’s focus to promote the indigenisation of key imported products to decrease dependencies on imports,” he says.

The company’s first product was the Extreme Cold Weather Clothing System (ECWCS), which passed its field test in 2017 and is currently manufactured by its Bengaluru-based original equipment manufacturer (OEM).

ECWCS is a 3-layer modular clothing system worn together, designed to operate in temperatures of up to –50 degrees Celsius. It is being used by Indian soldiers in high-altitude regions, including the Siachen Glacier.

“This clothing system has been imported for over 25 years. We can with pride say that AROO ECWCS outperforms the imported clothing systems provided to the Indian Army,” claims Bedi.

But clothing is just one item in a long list of defence products manufactured indigenously, and with time, finding buyers outside the country. More than 200 companies have been licensed to produce military equipment and participate in government tenders, preferably on their own, but also in collaboration with foreign companies, if needed.

In the defence sector, foreign direct investment (FDI) under the automatic route has been allowed up to 74 percent and up to 100 percent through the government route, wherever it may result in access to modern technology. Since the notification, the total FDI inflow reported till May 2022 is valued at a modest Rs 494 crore.

Speaking to Moneycontrol, Lt Gen Vinod Bhatia (Retd), India’s former director general of military operations (DGMO), said: “Indigenous defence production is a very positive step. If you aspire to be an important power, and talk of strategic autonomy, you need to produce your own military hardware. India is the only country in the world that imports arms and ammunition from all over: from Russia, the US, France, Israel, you name it. Indigenous defence production is long overdue, and it has started now.”

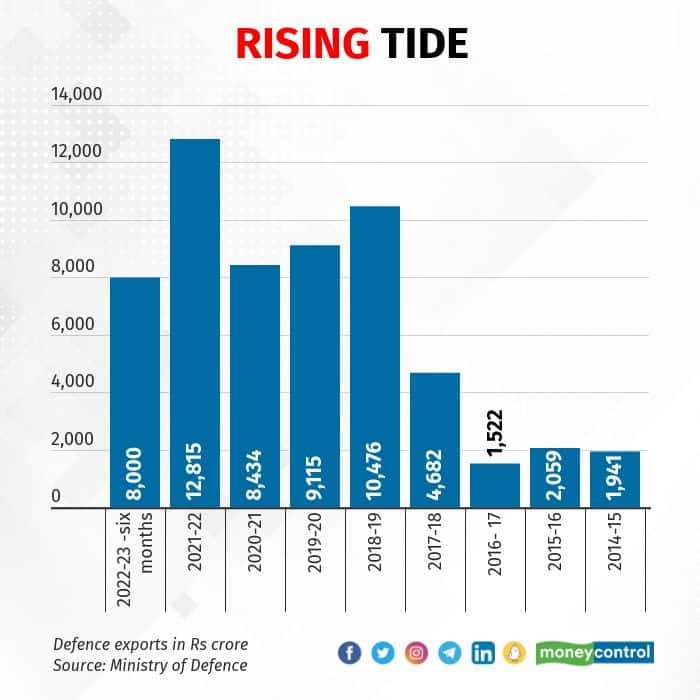

India registered defence exports worth Rs 8,000 crore in the first six months of the current financial year (FY) and aims to achieve an annual export target of Rs 35,000 crore by 2025, say government officials.

Last month, Defence minister Rajnath Singh said that India will target annual defence exports of Rs 35,000 crore by the end of FY 2025. Outgoing defence secretary Ajay Kumar said the country’s vision of Amrit Kaal (the next 25 years till India’s 100th year of independence) is aimed at making India one of the top five countries globally in defence production.

Make In India Effect

The government’s ambitious Make-in-India project seems to have spawned an unlikely export boom in the defence sector. Personal protective items, offshore patrol vessels, ALH Helicopters, SU Avionics, coastal surveillance systems, Kavach MoD II launcher and FCS, spares for radar, electronic systems, and light engineering mechanical parts, among others, are in the roster of exports.

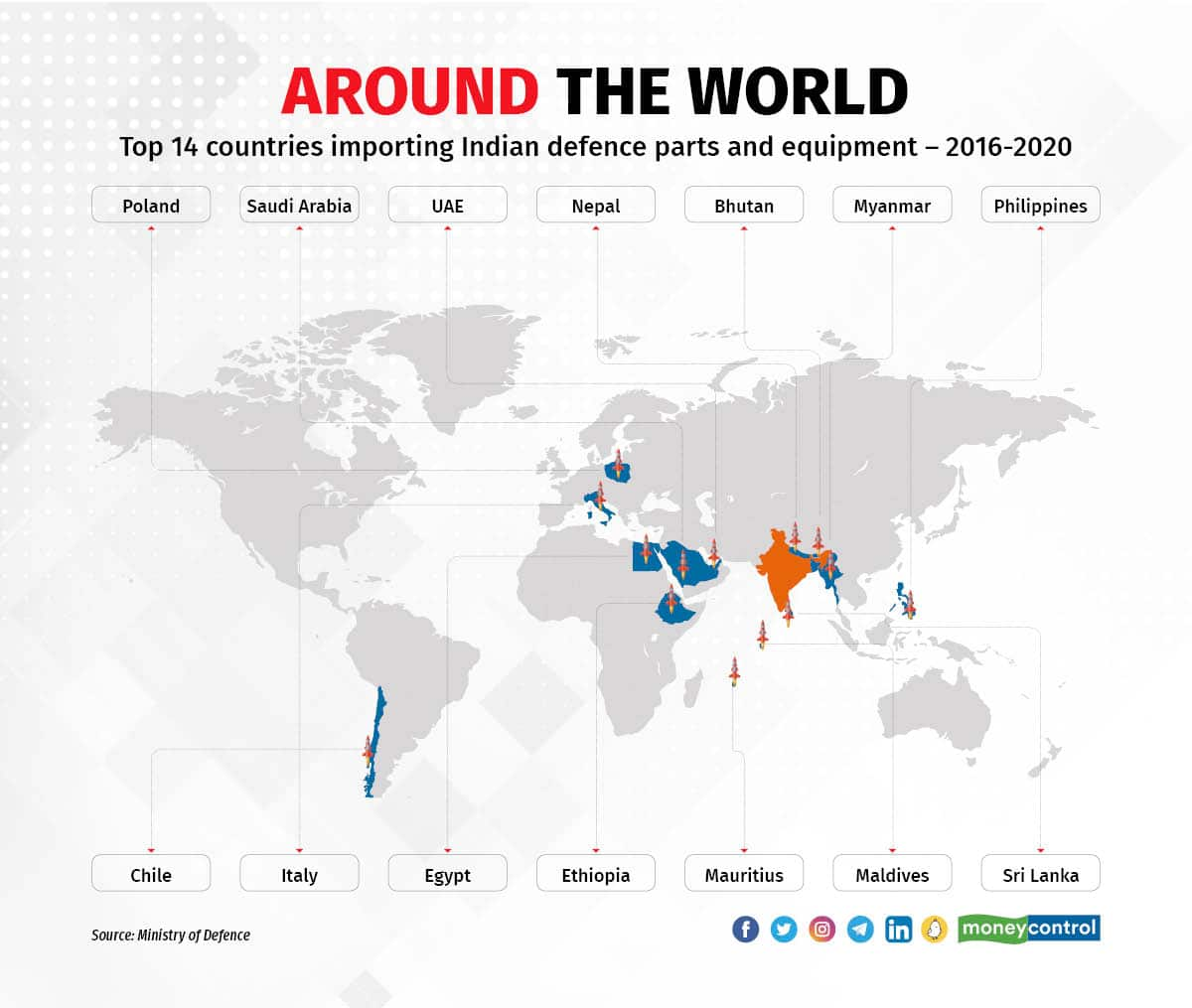

The ministry of defence (MoD) is also eyeing other contracts to boost defence exports. These include the sale of two Dornier military aircraft to Sri Lanka and Light Combat Aircraft (LCA) TEJAS. Both the aircraft are manufactured by state-owned Hindustan Aeronautics Ltd (HAL). In January this year, India and the Philippines inked a $375 million deal for the sale of Brahmos supersonic anti-ship cruise missile.

There are 16 Central Public Sector Undertakings (CPSUs) —including the likes of BEML, Mazagaon Shipbuilders Ltd, Advanced Weapons and Equipment India Ltd, and Armoured Vehicles Nigam Ltd —under the administrative control of the department of defence production, ministry of defence (MoD).

More than 50 Indian companies in the private sector have contributed to defence exports. India now exports defence products to 75 countries across the world from Italy and France to Chile.

“Today the world is trusting India’s technology because the defence forces of the country have proved the abilities of these products. The Indian Navy has included INS Vikrant in its fleet. This masterpiece of engineering has been made using the indigenous technology of Cochin Shipyard. The IAF has inducted Light Combat Helicopters made under the Make in India campaign and similarly, the Indian Army is buying indigenous field guns… The modern artillery being built at Hazira is defending the country’s borders...” Prime Minister Narendra Modi said while formally inaugurating DefExpo 2022 in Gandhinagar, Gujarat, on October 18.

He noted that “about 68 percent of India’s defence budget has been earmarked for Indian companies,’’ adding that “defence forces have created two lists of equipment; one is the list of equipment bought in the country and the second is items to be bought from overseas, if very necessary.”

So, as many as 411 items are being procured domestically.

A Mountain To Climb

Still, a report on Arms Production Capabilities in the Indo-Pacific Region, released by the Stockholm International Peace Research Institute (SIPRI) earlier this month, casts some ‘serious doubts about whether India will be able to significantly reduce its dependence on imports in the short and medium term’.

According to the report, 84.3 percent of the major conventional arms procured by India in 2016-2020 were of foreign origin, of which licensed production accounted for 57.8 percent. In stark contrast, domestic procurement accounted for a mere 15.7 percent of total procurement.

Yet, among the five segments monitored by SIPRI, the domestic shipbuilding industry stands out as a shining example of India’s potential in designing and manufacturing major platforms. Most of the ships delivered during the aforesaid period were based on Indian designs. And so was the nuclear-powered ballistic missile submarine Arihant, which gave ‘India’s nuclear forces a high level of autonomy’.

Unsurprisingly, the domestic shipbuilding industry accounted for 78.6 percent of the total volume of procurement of naval vessels by the MoD. It is widely believed that further progress depends on the Indian industry’s ability to locally design and manufacture propulsion systems and armament for the ships and submarines, the report noted.

According to the report, the Indian industry also did reasonably well in meeting 29.4 percent of the total requirement of air defence systems through locally designed equipment. However, it could meet only 6.3 percent of the overall requirement of aircraft and 7.7 percent of missile systems, with the rest of the requirement being met either through outright import or licensed production.

In 2021, however, even SIPRI concluded that India’s arms imports fell 33 percent between 2011-15 and 2016-20, at a time the country had taken a raft of measures to cut dependence on imported military hardware. The drop in arms imports was largely attributed to an attempt to reduce dependence on Russian arms and simplifying complex procurement processes.

Lt. Gen Bhatia believes private industry in India needs to get a leg up from the government and procedures and processes need to be simplified further. In addition, the two Defence Industrial Corridors being developed in UP and Tamil Nadu need to be speeded up.

Clearly reforms are the way ahead. Writing in the Financial Express, Amit Cowshish, former financial advisor (acquisition), MoD, cautioned against misreading the SIPRI 2022 observations, seeing in it an attempt to belittle Make-in-India.“The report should trigger an internal reassessment of the efficacy of the policies being pursued by the MoD and whether any course correction is required to achieve the intended objective of self-reliance in defence production…,” he said.

Ranjit Bhushan is an independent journalist and former Nehru Fellow at Jamia Millia University. In a career spanning more than three decades, he has worked with Outlook, The Times of India, The Indian Express, the Press Trust of India, Associated Press, Financial Chronicle, and DNA.

No comments:

Post a Comment