Indian Defence Production On Fast Track

HAL/ADA - TEJAS MK2 Medium Weight Fighter

HAL (Hindustan Aeronautics Limited) has logged a few major success stories. These include the operational clearance of Light Combat Aircraft Tejas. HAL has already received the go-ahead for producing 123 Tejas for the Indian Air

by Brigadier SK Chatterj

Five years back, we were still a million plus armed forces as we are today. However, the then Army Chief General VK Singh in his letter to the Prime Minister on 12 March 2012 informing that the army’s preparedness state was at an “alarming level”. The shrinking strength of the air force had no guarantees of resuscitation. The Navy’s much-touted plans of six submarines being manufactured at the Mazgaon Docks and Ship Builders Limited was running way behind schedule. The army was asking for over 1800 guns as replacements, but every reputed manufacturer, globally, had been blacklisted. The Navy’s air arm was barely capable of taking off. There was also no Make in India endeavour, the manual of Defence Procurement Procedure -2009 was an outdated mix that throttled private sector participation, exports and had little to offer for startups and MSMEs. Where are we today, given the fact that Vice Chief of Army Staff has only recently stated that 68 per cent of the equipment is as good as outdated?

As we brace for a general election, irrespective of the winner, it needs be said that the decks have been cleared and the tracks have been well laid for the next government to take off from where we stand in March, 2019.

Policy And Process

It’s relevant I recall a meeting we had in early 2016 with a Parliamentarian from the opposing camp who was one of the speakers in a seminar organised by us. The seminar was focused on innovation in the defence sector. The Defence Procurement Procedure draft DPP-2016 was already on the net for comments. The uninhibited evaluation, off the stage, of the Parliamentarian, was, “The draft DPP-2106 was path-breaking.” Manohar Parrikar had maintained the same pace and vigour all along his tenure as the Defence Minister as he did while framing the document.

The foremost achievement of the late Defence Minister Parrikar was the issuance of the DPP- 2016. Defence production, in the last five years, has grown 80 per cent to be pegged at Rs 80,000 crore in 2018-19. It was Rs 40,000 crore in 2013-14. Indigenisation has been the main thrust since then, with 150 contracts worth Rs 1,27,500 crore having been signed with Indian vendors for defence equipment. Acceptance of Necessity, the first of the major steps to be crossed that calls for the MoD’s (Ministry of Defence) concurring with the services’ projection of their specific requirements has been given for 164 proposals, worth Rs 2,79,950 crore for domestic production.

Defence exports have been given a substantial push, though a lot more needs to be done if we are to have a thriving defence industry. The increase has been more than modest in the last few years; a manifold growth from Rs 2013 crore in 2013-14 to Rs 7180 crore till the end of 2018. By the end of the financial year, we might even reach the five-figure mark.

A prime reason for the private industry not participating adequately in the defence sector had been the uneven play field we had so far for them. The DPSUs (Defence Public Sector Undertakings) and OFB (Ordnance Factory Board) have been the favoured lot notwithstanding their performance. However, though not ideal, yet the process of change has been set in motion.

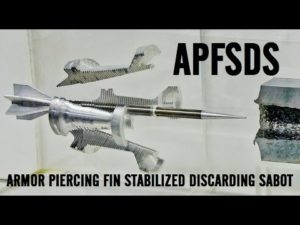

Armour Piercing Discarding Sabot

The new Make 1 & 2 procedures are attractive options loaded in favour of both entrepreneurs and Indian OEMs (Original Equipment Manufacturers). Make 2 that calls for government funding of the projects has drawn the industry to some critical areas. Among them are the 125 mm Fin Stabilised Armour Piercing Discarding Sabot (FSAPDS) for T-72 and T-90 tanks. The ammunition is critical in a tank to tank battle and our shortages in holdings were alarming. Other products likely to be delivered on the Make 2 plank include Infrared Search and Track System, Upper Air Sounding System and Manoeuvrable Expendable Aerial Targets.

The new Make 1 & 2 procedures are attractive options loaded in favour of both entrepreneurs and Indian OEMs (Original Equipment Manufacturers). Make 2 that calls for government funding of the projects has drawn the industry to some critical areas. Among them are the 125 mm Fin Stabilised Armour Piercing Discarding Sabot (FSAPDS) for T-72 and T-90 tanks. The ammunition is critical in a tank to tank battle and our shortages in holdings were alarming. Other products likely to be delivered on the Make 2 plank include Infrared Search and Track System, Upper Air Sounding System and Manoeuvrable Expendable Aerial Targets.

The production of a fair number of items has been de-licensed. More private players have jumped onto the bandwagon to profit from the billions of dollars’ worth purchases of the armed forces for their modernisation. Till the 31 March 2014, there were 215 licensees for defence equipment production. Now, notwithstanding de-licencing production of large numbers of items, 424 licensees are in the field.

Other policy reforms that deserve mention include a Strategic Partnership Model in the DPP 2016. Currently, the approval for two important proposals for fighter aircraft and submarines have been given under this category.

Foreign investment has been enhanced to 49 per cent through the automatic route and beyond that with due government approval.

Lately, 116 items procured by Defence PSUs have been notified under the Public Procurement Order which mandates giving preference to domestic manufacturers. Defence testing labs and firing ranges have been made available to the industry for testing and certifications.

Performance of DPSUs & OFB

At least some of the defence PSUs and OFB, more often cited for their sluggish pace and indifferent performance, have quite an enviable report card to display, today. As per reports, they have indigenised over 10,000 parts during the period 2014–18.

The issue of ammunition deficiency is being addressed by the OFB in concert with private sector companies.

Further, Arjun Mk-2 is ready for induction while licensed production of Russian tanks is being pursued. Specialised clothing for high altitude areas was being almost entirely imported. Today, 80 per cent of such clothing is of Indian origin, and the objective is to achieve 100 per cent indigenisation in the next two years.

Major Weapon Systems & Platforms

They have also developed a few major platforms to include 155 mm Dhanush howitzer based on the old Bofors design. An announcement regarding production of AK-203, with Russian collaboration, at Amethi has been made and should materialise in the not too distant future. This rifle will replace the INSAS, a weapon that has never enjoyed the confidence of the soldier who carries it as his personal weapon.

Force. HAL has added quite a few feathers to its cap as far as helicopters are concerned. Apart for Advanced Light Helicopter, Light Combat Helicopter is under development. As far as trainer jets are concerned, both basic and advanced trainer jets are being developed.

As far as Naval platforms are concerned, maximum progress in indigenisation has been achieved by the Navy. In fact, now the objective is to produce submarines entirely in India. Currently, six submarines are in various stages of construction and operationalisation, with INS Kalavari having been already inducted in the naval fleet. Heavyweight torpedoes for the Navy are also in the process of being manufactured in the country.

Defence Industry Corridors

In February 2019 the Government announced the setting up of two defence industry corridors in Uttar Pradesh and Tamil Nadu. Investments of over Rs 3,700 crore were announced by a combination public and private sector enterprises in August 2018 for the Uttar Pradesh hub. The plans for Tamil Nadu are due to be announced in January 2020.

Innovation For Defence Excellence

The iDEX initiative aims to take advantage of the innovative capital of India’s startups. Ministry of Defence has introduced “Innovations for Defence Excellence” (iDEX) initiative which was launched by PM Modi in April 2018. iDEX had offered 11 challenges in August 2018 that encompassed operational issues faced by the defence forces. 520 responses were received. These are being processed. Successful applicants would be eligible for Rs 1.5 crore as support. Four more challenges were released keeping in view the enthusiasm encountered in the first round. Submissions for these challenges is in progress.

Suo-Moto Proposals

The process aims to capitalise on the creativity of startups, by allowing them a chance to offer their solutions for use by the armed forces. The system does away with the requirement of issue of RFP (Request For Proposal) by the services and allows the industry to make a suo-moto offer of their products. 113 such proposals have been received so far and four of these have been accorded Approval-in-Principle.

Defence Investor Cell (DIC)

DIC was launched in January, 2018 and provides an online interface assisting MSMEs. Using the platform, over 350 MSMEs have progressed their issues. Several payments have been processed while in many other cases updated information on projects has been provided.

Artificial Intelligence (AI)

AI will play a critical role in the modern battlefield and is a priority area for defence production. Development of 25 AI based products and applications for military use have been initiated.

Raksha Gyanshakti Mission

The objective of the mission is to move the Indian defence production ecosystem from licenced manufacturing to an innovation-based sector. It also serves the need to have greater IPR in defence products. Since November 2018, when the mission was launched, It was decided to train 10,000 personnel of DPSUs, in batches. A target of filling 1000 new IP by 2018-19 was the objective. By October 2018, 3,500 personnel had been trained and 150 new patents filed. The mission will be extended to cover the MSMEs and other industries in the defence sector.

The country has made deliberate strides, though not long enough. A lot will depend on building on the momentum that has been generated. For a change, the MoD is viewed more as a partner by the three services. What would be critical is the national leadership’ will to strengthen the nation’s defence in a rather vulnerable scenario in our region. It needs to be remembered that neither Kargil nor Doklam was predicted. We have to be prepared for bigger challenges as we go along and gather strength.

No comments:

Post a Comment